Raw Materials Used

| Material | Used For | Specification |

|---|---|---|

| Electrolytic Copper | Conductors | ≥ 99.97% purity (IS 8130:1984) |

| Aluminum Rods | Conductors | EC Grade (IS 8130:2013) |

| PVC Compound | Insulation/Sheathing | FR, FRLS, HRFR, Type A/B (IS 5831:84) |

| XLPE | Special cables | For high temp or voltage apps |

| Galvanized Steel | Armoring | IS:3975 |

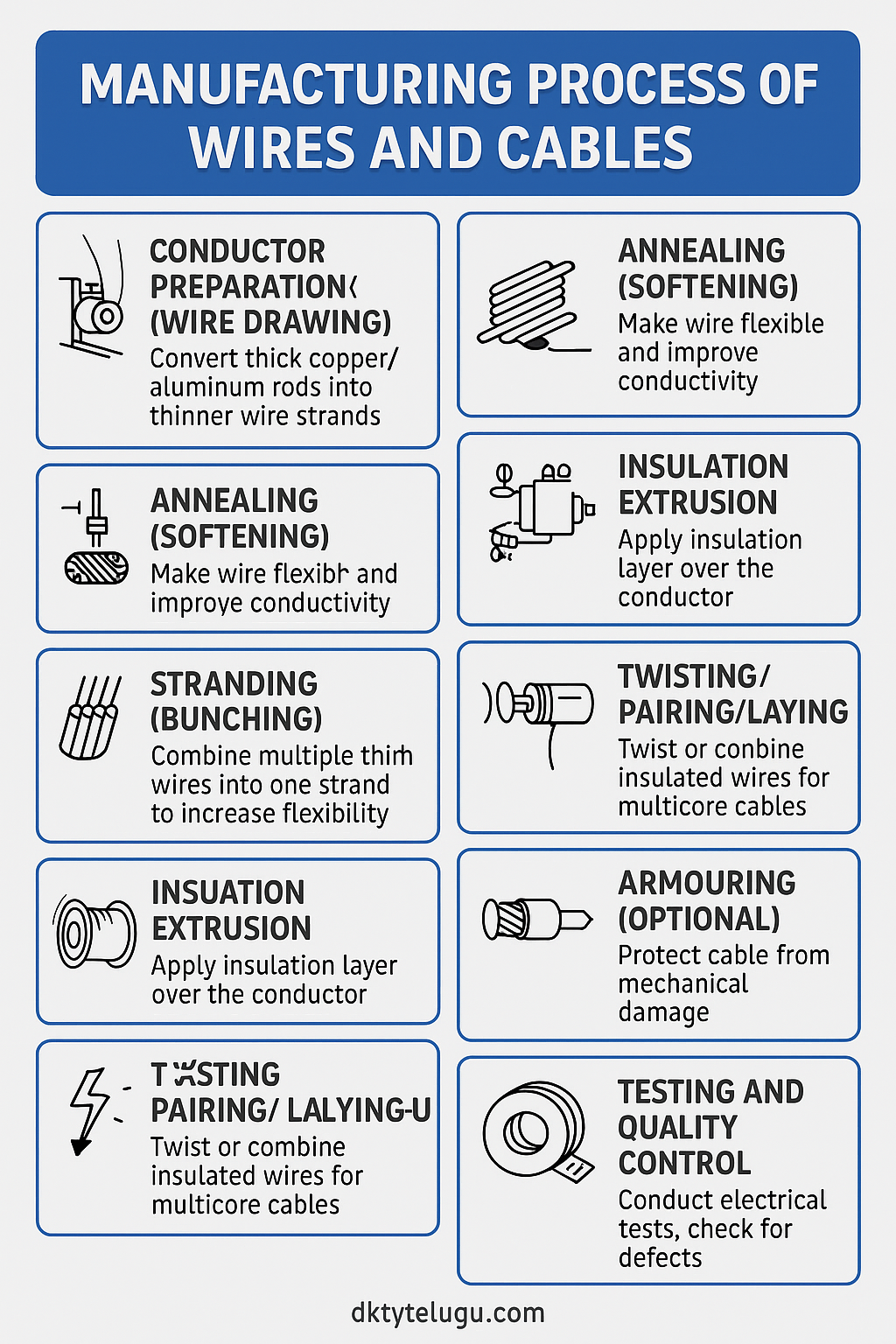

Step-by-Step Deep Manufacturing Process

1️⃣ Wire Drawing (Breakdown of Rods to Fine Wires)

- Input: 8 mm Copper/Aluminum Rod.

- Machine: Rod Breakdown Machine (multi-die or single die).

- Process:

- Rod passes through carbide dies to reduce diameter to 1.5mm–0.5mm.

- Speed: 25–35 m/s.

- Cooling: Through lubricant emulsion or water.

- Tension Control: Maintained by dancer arms or loop controllers.

Critical Check:

- Surface finish must be smooth.

- No burrs or cracks.

2️⃣ Annealing (Softening Conductors)

- Purpose: Enhances conductivity & flexibility by removing drawing stress.

- Machine: Online or offline annealer.

- Process:

- Heated to 350–500°C.

- Passed through nitrogen (inert) atmosphere to avoid oxidation.

- Then cooled quickly in water.

Critical Check:

- Final resistivity ≤ 0.01724 Ω·mm²/m (as per IS 8130).

- Elongation should be ≥ 20%.

3️⃣ Bunching / Stranding

- Purpose: Combine several wires into 1 flexible conductor.

- Machine: Bunching or stranding machine (planetary or rigid strander).

- Standard: IS 8130 class 2 or 5.

- Types:

- 7/0.3 mm

- 14/0.3 mm

- 36/0.3 mm etc.

- Lay length controlled for optimal flexibility and conductivity.

Critical Check:

- Conductor must be circular and compacted.

- No wire overlaps or uneven twists.

4️⃣ Insulation Extrusion

- Machine: Extrusion Line with crosshead and extruder (typically 60–90mm screw).

- Material: PVC, HR PVC, FRLS, LSZH, XLPE.

- Temperature: 140–170°C (varies by compound).

- Die: Controls insulation thickness (usually 0.6mm–1mm).

- Cooling: Water trough after extrusion.

Critical Check:

- Concentricity and uniform thickness.

- Spark test at 6–10 kV inline (detects pinholes).

- Adherence of insulation to conductor.

5️⃣ Coloring / Striping (Optional)

- Done for identification of wires in multi-core cables.

- Method: Inline inkjet printer or co-extrusion with colored PVC.

6️⃣ Twisting or Laying Up (Multicore Cables)

- Machine: Laying up machine.

- Core Types: 2, 3, 4, or 5 cores.

- Lay Pitch: Adjusted based on cable type.

Critical Check:

- No crossing or gaps between cores.

- Correct color code (as per IS 694).

7️⃣ Inner Sheath (for Multi-core or Armoured Cables)

- Material: Type ST1/ST2 PVC compound (IS 5831).

- Purpose: Bind the cores and provide a bedding for armoring.

- Thickness: As per IS 1554 standards.

Critical Check:

- No air gaps or wrinkles.

- Uniform bedding without breaks.

8️⃣ Armoring (Optional)

- Material: Galvanized Steel Strip (STA) or Wire (SWA).

- Process:

- Applied helically using armoring machine.

- Covered over inner sheath for protection from mechanical damage.

Use Case: For underground cables, industrial power cables.

9️⃣ Outer Sheathing (Final Layer)

- Material: PVC (FR/FRLS/HRFR), PE, or LSZH.

- Machine: Sheathing Extrusion Line.

- Markings: Brand name, size, ISI mark, voltage, year.

Critical Check:

- No burn marks, air bubbles, or color mismatch.

- Hot Spark Test (as per ISI) to check for surface defects.

Final Quality Control & Testing

Standard Tests (As per IS 694/IS 1554)

| Test Name | Parameters Checked |

|---|---|

| Conductor Resistance | Ohm/km (at 20°C) |

| Insulation Resistance | MΩ·km |

| High Voltage Withstand Test | 3 kV for 5 minutes (PVC wires) |

| Elongation & Tensile Strength | PVC: >100%, Tensile >12.5 MPa |

| Spark Test | 6–10 kV AC for insulation pinhole detection |

| Flammability Test | Flame spread under controlled flame (FR test) |

| Oxygen Index Test | For FRLS/LSZH wires – must be >29% O₂ |

| Smoke Density Test | For FRLS – measured in Ds units |

Coiling, Printing & Packaging

- Length: 90m / 100m standard coils.

- Packaging: Shrink-wrapped or boxed.

- Label Includes:

- Cable type (e.g., 1.0 sqmm FR)

- Voltage grade (e.g., 1100V)

- ISI license number

- Manufacturing date

- MRP and barcode

🔴 DKTV Telugu – మీకు ప్రతిరోజూ తోడుగా!

DKTVTelugu.com బ్లాగ్లో మీకు ప్రతి రోజు గోల్డ్ రేట్లు, స్టాక్ మార్కెట్ అప్డేట్స్, ప్లాస్టిక్ మరియు మెటల్ ధరలు, ఎలక్ట్రికల్ ఉత్పత్తుల తయారీ సమాచారం అందించబడుతుంది.

📌 మమ్మల్ని ఫాలో అవ్వండి: YouTube, Instagram, Telegram

మాన్షన్ కేబుల్స్ (అనగా హౌస్ వైర్లు) ఎలా తయారవుతాయి అనే వివరాలు ఈ బ్లాగ్లో తెలుసుకుందాం. ప్రతి దశలో ఉపయోగించే యంత్రాలు, పదార్థాలు, మరియు టెస్ట్ల వివరాలు ఇక్కడ ఉన్నాయి.

DKTV Telugu Official Links

Website (Main Blog):

🌐 https://dktvtelugu.com

📺YouTube Channel:

https://www.youtube.com/@dktvtelugu

📸 Instagram:

https://www.instagram.com/dktvtelugu

📢 Telegram Channel:

📲 https://t.me/dktvtelugu

✍️ Quora Profile:

🔍 https://www.quora.com/profile/DKTV-Telugu

📘 Facebook Page:

https://www.facebook.com/dktvtelugu

📌 Pinterest:

https://www.pinterest.com/dktvtelugu

🐦 X (Twitter):

https://twitter.com/dktvtelugu

💼 LinkedIn:

🔗https://www.linkedin.com/company/dktvtelugu

📲 WhatsApp Channel (if available):

https://whatsapp.com/channel/dktvtelugu (Update this if you have the correct link)